Toxic Fumes-Gases (Download)

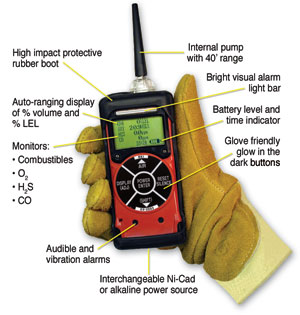

TOXIC FUMES/GASES 1 Toxic Fumes Toxic fumes of various types might be encountered on construction sites. Typical fumes include carbon monoxide, methane, hydrogen sulfide, chlorine, and gases/fumes that displace oxygen, including nitrogen, argon, etc. 2 Toxic Fumes/Gases Toxic fumes are often odorless and since there are many types, one cannot rely on a sense of smell alone. This is why air monitors should be used in environments where of various types might be encountered on construction sites. Air monitors must be understood in order to used them properly, 3 Air Monitors 4 What is an Air Monitor? It is commonly a battery- powered device that draws air through a medium and evaluates the air quality. Alarms or alerts are activated when unacceptable levels of toxicity are noted or when inadequate oxygen is present. 5 Why is Air Monitoring Important? Construction workers are frequently in danger of inhaling toxic fumes/gases in work areas which may result in death. Sufficient levels of oxygen must also be observed to ensure worker safety. To avoid such accidents, the air on construction sites has to be monitored to ensure that the air quality remains within permissible limits. 6 Sources of Fumes/Gases Toxic fumes/gases can come from a variety of sources. Many of these sources are in products such as bleach, chlorine, paint, kerosene, paint thinner, pesticides, etc. Dangerous fumes/gases can be found in excavated areas whey they may occur naturally in the ground . http://www.familymanagement.com/childcare/facility/chemical.toxins.safety.html 7 History of Air Monitoring Practice of air monitoring begun in 1911. Canaries were used to alert miners of toxic fumes. The canary is particularly sensitive to toxic fumes/gases such as carbon monoxide which is colorless, odorless and tasteless. When the canary stopped singing, it signaled a problem for the miners. Miner with caged canary http://www.petcaretips.net/canary-coal-mine.html 8 History of Air Monitoring Canaries are no longer used in mining operations or in any air monitoring application. The last canaries were used in 1986 in England. Miners with caged Canary http://www.sfgate.com/cgi-bin/blogs/pets/detail?entry_id=28551 9 Terminology Action Level (AL) – Indicates the level of a harmful or toxic substance/activity that requires remedial actions Time Weighted Average (TWA) – The average exposure to a contaminant to which workers may be exposed without adverse effect over a period such as in an 8-hour day or 40-hour week 10 Tools and Equipment Personal Sampling Pumps These pumps are one method of inspecting the air in the work environment. They are small and compact so that the worker can transport them easily while working. SKC Pocket Pump 210 Series http://www.skcinc.com/pumps/210-1000.asp 11 Safety Concerns There are three major ways to harmfully come in contact with toxic fumes/gases, or oxygen deficient air: Inhalation Breathing in the gas Ingestion By means of swallowing these fumes Dermal Contact Gas that can penetrate through the skin to cause damage http://www.stewardshipcommunity.com/stewardship-in-practice/human-health/hazard-risk-human-health-and-pesticides/hazard-profile-and-risk-assessment.html 12 Toxicity Assessment Dose is the AMOUNT of substance to which one is exposed. The less the toxicity, the greater the dose one can tolerate without ill effects. The greater the toxicity, the less dose one can tolerate without becoming sick. http://www.free-training.com/osha/hazcom/hhaz/64.htm 13 Fatalities Fatalities related to in clude death by lack of oxygen and overexposure to toxins/gases such as hydrogen sulfide, carbon monoxide, and chloride. Over 70 construction worker deaths , specifically related to toxic fumes/gases were investigated by OSHA from 1990-2009. (Source: Extracted from OSHA Accident Investigation Data 1990-2009”) 14 OSHA Regulations OSHA 1926.800 Underground Construction OSHA requires the monitoring of airborne contaminants “as often as necessary” depending on the location of jobsite, geology, previous history of contaminants from nearby worksites, and work practices that may be occurring nearby (running of a diesel engine). Oxygen levels must be kept between 19.5%-22% 15 OSHA Regulations OSHA 1926.910 Inspection After Blasting “Sufficient time shall be allowed, not less than 15 minutes in tunnels, for the smoke and fumes to leave the blasted area before returning to the shot.” OSHA Subpart Z- Toxic and Hazardous Substances OSHA 1926.651- Hazardous Atmospheres 16 PPE Requirements Proper Air Monitoring Equipment Personal Sampling Pumps Coated Filters Electric Monitors Vapor Monitor Badges Respirators Supplied Air Air Purifying Air purifying respirator http://cenvironment.blogspot.com/2011/02/clean-air-for-construction-workers.html 17 Air Monitoring Best Practices Survey the work area to identify the presence of toxic materials Anticipate areas where workers might be exposed to naturally-occurring toxic gases Position internal combustion engines so that the exhaust (carbon monoxide) does not accumulate and endanger workers 18 Air Monitoring Best Practices While many toxic fumes/gases are colorless and odorless, they are also extremely dangerous and need to be properly monitored. Workers should place air monitoring devices as close to the face as possible to ensure that the air being monitored is the same air being inhaled. 19 Air Monitoring Best Practices If a worker succumbs to air poisoning or oxygen deficiency, emergency crews or other workers must remember to take proper precautions when attempting a rescue so that they too do not become victims. http://www.msha.gov/district/dist_07/rescue/rescue.htm 20 Think Safety Work Safely 21