Lighting (Download)

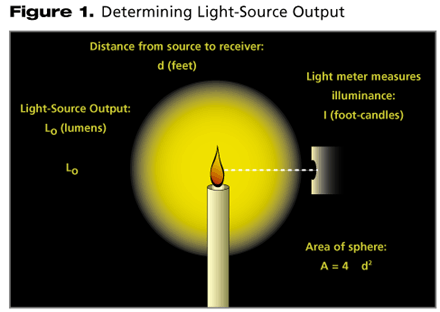

Lighting 1 Lighting in Construction Safety 2 Potential Effects of Inadequate Lighting: Unsafe working conditions resulting in injury/ death Loss of Productivity Blurred vision, headaches, eye strain Compromising the Quality of Work 3 Lighting – Is it Important ? Insufficient lighting can cause: Unsafe working conditions resulting in Injuries from unseen hazards/ death. Loss of productivity. Loss of quality. Eye strain Blurred Vision Head aches A reduction in mental alertness If a worker cannot see, a worker cannot work. 4 Why is Good Lighting Important? Increases Productivity Enhances Comfort Most importantly improves safety 5 Amount of Temporary Lighting needed depends on… Size or design of building Working Hours Time of the Year Weather Conditions 6 Aspects of Adequate Lighting: Quantity Only quantity of light is measurable ( footcandles ) OSHA uses quantity to establish minimum standards for illumination Improper Contrast Brightness Glare Reflection 7 Determining Foot-candles A foot-candle is a unit of measure of the intensity of light falling on a surface, equal to one lumen per square foot. 8 A light meter can be used to measure the number of foot candles. 9 Area = 1 sf 1 ft 1 Lumen How to measure lighting ? Lighting is measured by foot candles 1 Foot Candle = The amount of light given off by one candle on a surface one foot away 10 At about 200 foot-candles most people begin to squint. This is when sun glasses are appropriate. 11 It is more than the light source ? . The color of the surrounding surfaces The shape of the surrounding surfaces The texture of the surrounding surfaces The location of the light source in the room 12 Example This is an example of a living room that reads 10 foot candles. 13 Example 2 This kitchen reads about 25 foot candles 14 Example 3 This grocery store reads about 150 foot candles 15 Example of measurements within the same room The same room can have a measurement variance that may exceed 200 foot candles depending on the location where the measurements take place. 200 FC 50 FC 45 FC 5 FC 16 Common Misconception People often think lighting is only a problem if it is too dark but lights that are too bright can also be dangerous Having to work in awkward positions because light is in the eyes can cause eye strain and head aches making work more dangerous 17 Other poor lighting problems Poor lighting can lead to myopia (nearsightedness ), increased headaches, and increased stress 18 According to the OSHA Accident Investigation Data from 1990 thru 2007 There were seven deaths that can be directly attributed to poor illumination. Source: Extracted from OSHA Accident Investigation Data 1990-2007 19 Accident Summary Worker was inside a 180 ft diameter dome, greasing the pins on an excavator bucket. A 10-wheel dump truck with an inoperable back-up alarm backed into the dome, heading toward the excavator bucket. The excavator engine was running and the worker neither saw nor heard the dump truck approach. The truck driver’s vision was impaired by the change in lighting from outside to indoors and did not see anyone around the backhoe. The right rear corner of the dump truck struck the excavator bucket, pinning the worker between the truck and the bucket. He sustained massive internal injuries, and was killed. Source: Extracted from OSHA Accident Investigation Data 1990-2007 20 Accident Summary A company was pouring a foundation adjacent to a recently constructed area that contained pits about 11 feet deep. The pits had been covered with plywood and sheet metal to guard the open surfaces. A worker was using a Fresno to smooth out freshly poured concrete. A welder needed to perform welding in the pit area, but lacked adequate lighting for the job. A cover was removed from the pit to allow sunlight to penetrate the space, providing light for the welder. A worker who was focused on the work, stepped back into the unguarded space and fell to the surface below. Source: Extracted from OSHA Accident Investigation Data 1990-2007 21 Accident Summary A worker was using a metal bull float to finish a concrete highway slab. The bull float had a 19′ handle and the power lines were 17′ above the ground. The work was being done at the end of the day when it was dark. No temporary lighting was installed. The worker raised the float and struck an energized overhead power line The worker was electrocuted. Source: Extracted from OSHA Accident Investigation Data 1990-2007 22 Case of Too Much Light At 9:00 AM, a worker was putting a steel deck roof on a large tilt up structure. He walked out to the edge of the roof deck. The glare of the morning sun may have caused him to be unable to distinguish the steel roof decking from the white vinyl sheet used to support the insulation. He fell through the vinyl to the concrete floor 33’-6” below. The injuries proved fatal. Source : Extracted from OSHA Accident Investigation Data 1990-2007 23 Case of Too Much Light A worker was crushed by a road grader that was backing up. It pinned the worker against a pickup killing him. The afternoon sun and dirty glass caused excess glare for operator. 24 Case of too Little Light Worker was walking in a mall under construction to throw trash away. On the way to the dumpster he stepped into a two foot depression in the floor. He tripped, causing lower back injury. Nearest light source was 150’ away. “Source: Extracted from OSHA Accident Investigati7n Data 1990 – 2008” 25 Case of Too Little Light Uncovered hole in floor Single tinted window was the only light source in the room Laborer stepped in the floor opening and fell to the floor below A study showed only .2 foot-candles in area where he fell! 26 According to OSHA, 289 fatality cases were recorded between 1990 thru 2007 as visibility related cases. Most of the 289 cases had a direct link to the amount of lighting where the accident took place Fatalities “Source: Extracted from OSHA Accident Investigati7n Data 1990 – 2008” 27 OSHA Subpart C 1926.26 Construction areas, aisles, stairs, ramps, runways, corridors, offices, shops, and storage areas where work is in progress shall be lighted with either natural or artificial illumination. 28 OSHA 29 Subpart K 1926.405 (a) 2