Crowbars (Download)

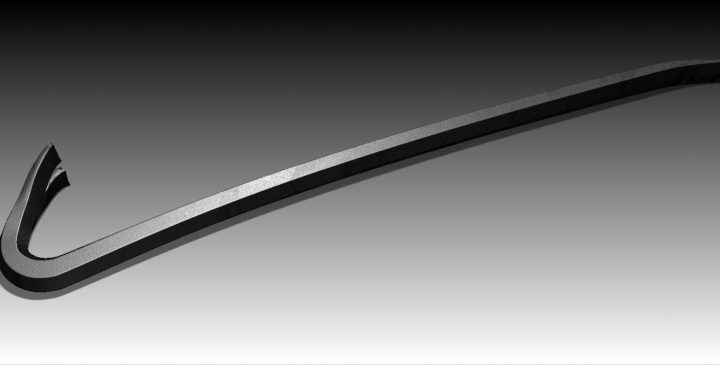

Crowbars, Wrecking Bars, & Pry Bars 1 Definition Wrecking bars and crowbars are used for some of the same purposes and are considered by many to be the same tool (others consider these tools to be distinct and different) A basic crowbar is a straight metal rod with a curved end. The term crow refers to the slotted tip used for pulling nails, which resembles a crows foot or beak. 2 Wrecking Bar/ Crowbar Used for demolition and pulling nails One end has a crows foot and the other has a smooth sloped edge Can also be used for prying Range from 14 to 36” long www.Lowes.com The terms (wrecking bar and crowbar) are used interchangeably in this presentation 3 Pry bar Made from medium carbon steel Range from 7 to 21” long Used mostly for pulling nails Both ends have V shaped indents to fit around nails for pulling www.Lowes.com 4 Uses A crowbar is used as a lever to force objects apart or remove nails Demolition work is commonly where crowbars are used Warehouses are typical hosts to crowbars as the tool is useful in opening boxes Also used to remove concrete forms 5 Safety Concerns Electrical Shock – Typical crow bars are made of steel or iron. If these bars come in contact with a live wire, electrocution can result. Manufacturers produce non-conductive bars to protect against this. 6 Safety Concerns Falls – When applying a large force to a lever, the recoil after using the tool can be large enough to throw a worker back. The worker must be aware of the force and be securely positioned before using the tool. 7 Example injury case A worker used a crowbar to clear the blockage in the opening of an operating jaw crusher. The crow bar bounced off the jaw wall and hit the resting hand of the worker. Another worker came to finish the job and injured himself in the same manner. Source: Extracted from Department of Mines and Energy Safety Alert #10 4/5/200 8 Fatalities In a period of 20 years, approximately 32 pry bar/crowbar accidents were investigated by OSHA. The majority of the accidents were due to falls. Source: Extracted from OSHA Accident Investigation Data 1990-2009 9 Example case A worker was attempting to drive a pry bar through an epoxy liner of a manhole so that water from the installation process would drain into the invert. He fell into the manhole into approximately 10 inches of water at a temperature of approximately 180 degrees and received burns on his body . Source: Extracted from OSHA Accident Investigation Data 1990-2009 10 Example Case A worker straddled trusses while trying to adjust the girder truss with a pry bar. The pry bar slipped, he lost his balance and he fell approximately 15 feet to the concrete floor below . Source: Extracted from the OSHA Accident Investigation Data 1990-2009 11 Example Case A worker was in the process of installing foundation support brackets and bolts to the foundation of a condo residence. He was installing a bracket in the area of an exterior electric hot water heater on the patio. The worker had installed the hold down bolts and was attempting to straighten the bolt with a pry bar. It appears that the pry bar, which was pressed against the wall support stud, came into contact and pinched or otherwise broke the insulation on a piece of Romex wire which was energized by a 110 volt electrical circuit. The worker suffered a fatal electrical shock when his pry bar made contact with the 110 volt circuit. Source: Extracted from OSHA Accident Investigation Data 1990-2009 12 Example Case An worker was cutting a concrete curb and slab into a building support column. In an effort to complete the cut into the column the worker raised the saw blade guard. At completion of the cut the worker backed the saw away, still running, from the column and proceeded to us a pry bar to remove the concrete. The concrete slabbed off causing the pry bar to slip causing the employee to fall back onto the saw. The worker was fatally cut across his back and side. Source: Extracted from the OSHA Accident Investigation Data 1990-2009 13 Example Case A worker was removing mechanical equipment. When removing a part with a pry bar, the bar slipped from underneath the pad and the worker fell backwards and landed on his buttocks. He tried to catch himself but he landed at the edge and fell 29 feet head first and died. Source: Extracted from OSHA Accident Investigation Data 1990-2009 14 Example Case A superintendent for a general contractor, went to an inactive job site. He was apparently prying loose a 2 by 6 board that was bolted to the outside of the building near the top to allow the roofers to slip flashing behind it. While he was pushing on a crow bar to loosen the board, he fell 33 feet to his death from the flat roof. Extracted from OSHA Accident Investigation data 1990-2009 15 Example Case A carpenter’s helper, was attempting to free a stuck auger from a guide by using a pry bar. When the auger was freed, it slid forward out of the guide and caused the pry bar to strike the worker on the right side of his head. He later died as a result of this injury . Extracted from OSHA Accident Investigation data 1990-2009 16 Example Case A n employee was starting to loosen a stone with a pry bar. For some reason , the employee lost his balance and fell, striking the fire escape, then the sidewalk. The employee was killed . Extracted from OSHA Accident Investigation data 1990-2009 17 OSHA Regulation Crow bars, wrecking bars and pry bars are not specifically mentioned in any OSHA provision. 18 PPE Be sure to wear a hard hat if working around other people while prying Wear gloves to prevent slippage of the bar and to prevent blisters Wear steel toed boots in case a bar falls 19 Best Practices Evaluate and assess where the action of the crowbar will be when it is taking place, whether it be high in the air or around others Beware of energized electrical wires around work area Strive to be solidly planted when using a crow bar. Do not reach over ledges or use the bar as an extension of the arm. Fall hazards are a serious concern. Use both hands and be aware of where the bar is pointed. 20 Think Safety Work Safely 21